Ever-changing Research

A long journey from shapes to materials and back, made of experimenting, discoveries, falling and rising again.

Ceaselessly.

1999

CARVING.

Focusing on woodworking by traditional manual tools. Eventually, moving to cutting and milling power tools.

2007

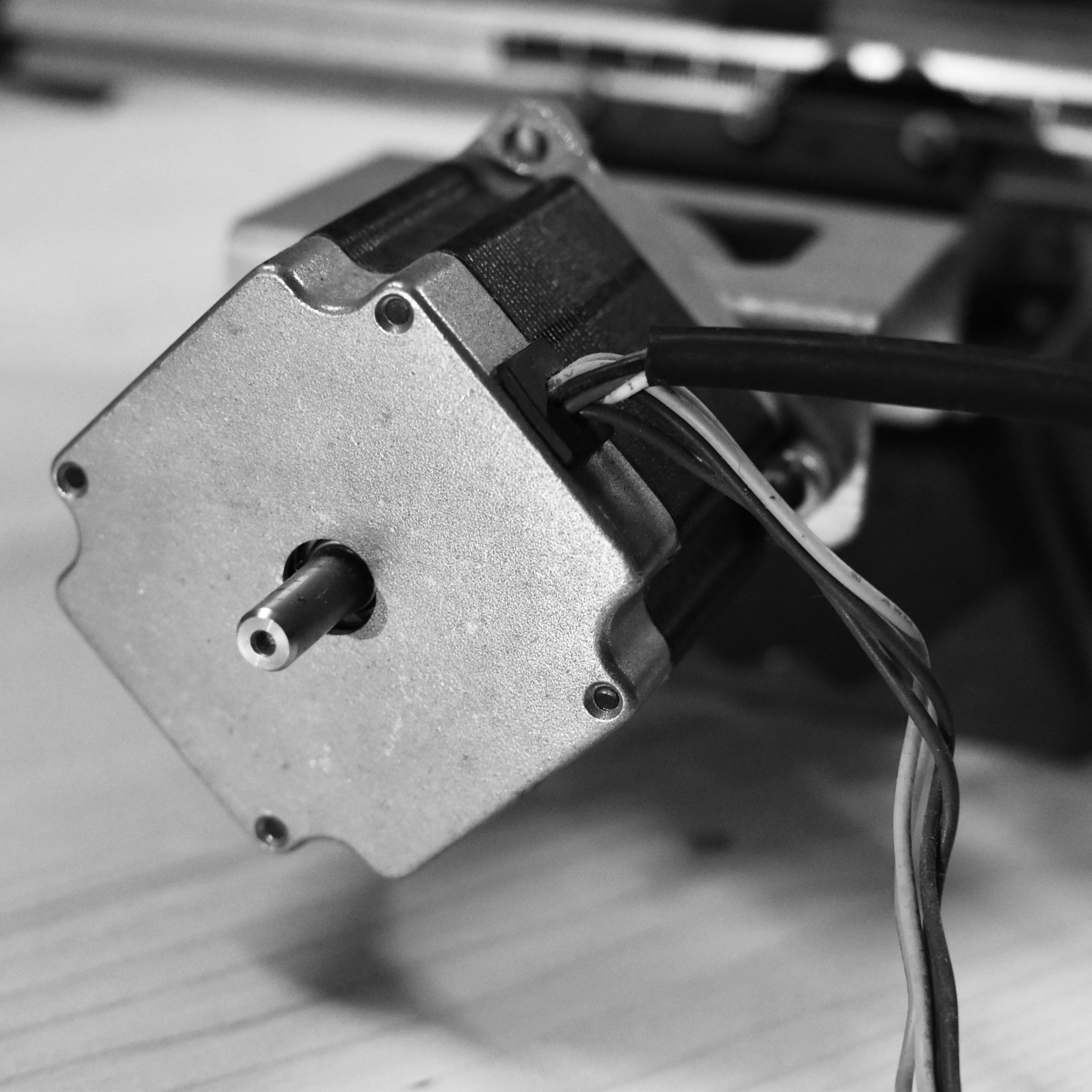

AUTOMATION.

Launching CNC-based working methods, especially CAD/CAM applied to milling. Beginning to explore the potential of 3D modeling .

2013

ADDITIVE MANUFACTURING.

A new point of view in Sculpture making: not only material removal from solid blocks but also depositing it wherever needed.

Improvements in form finding by digital methods.

Launch of a new production line entirely based on additive manufacturing processes.

2017

MOULDING & CASTING.

Combining subtractive and additive methods to enhance traditional sculpting performed so far. Digital brainstorming, rapid prototyping via CNC and additive manufacturing, moulding and casting for final products. Digital working can now be performed also by parametric design.

2018

LIGHT.

Enhancement of light in Sculpting.

Focusing on specific transparency, translucency and opacity for different materials, in order to better control light effects over artworks.

Introducing epoxy and UV resins. Improving research on glass and its interaction with light.

2019

TURNING.

Regular patterns are now achieved by turning.

Further pottery making by embedding organic items within epoxy. Improvements in mould making to minimise the waste when turning.

2020

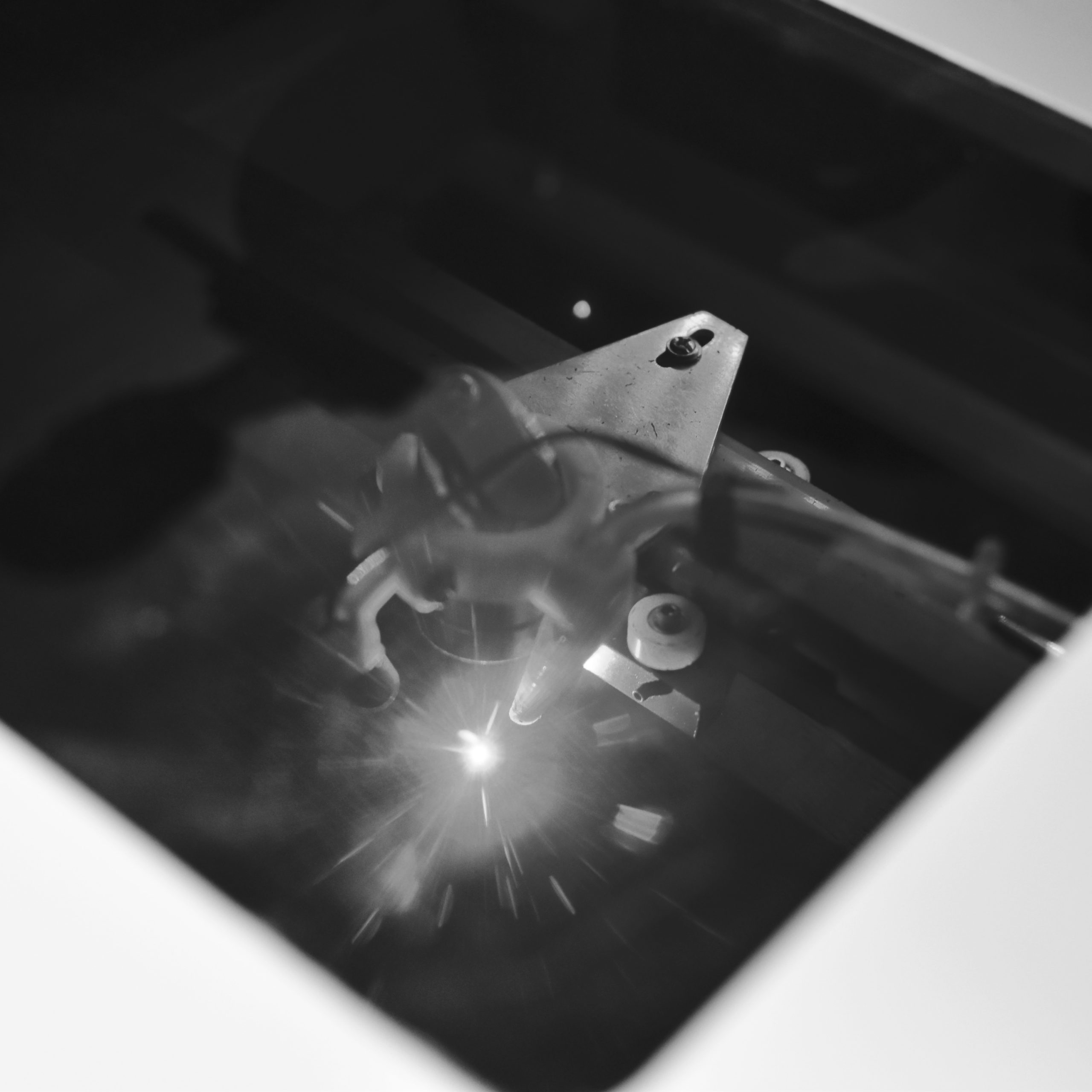

LASER.

Use of different types of lasers to get the most accurate cutting and engraving. Hard stones unsuitable for traditional sculpting tools can now be easily machined.

Further experimenting on laser and clear epoxy for enhanced light effects.